Your benefits in the spotlight

Advanced features and process advantages

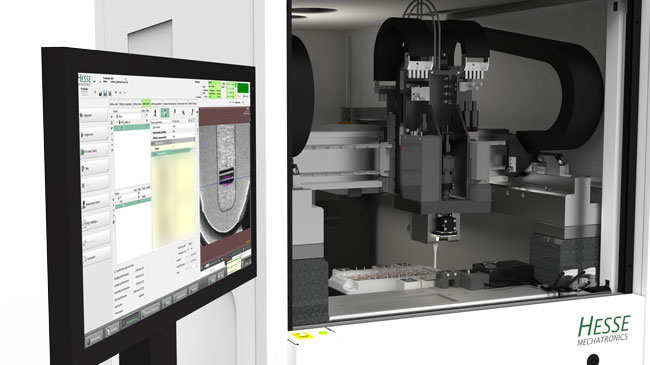

- Fully automatic ultrasonic welder with a very large working area

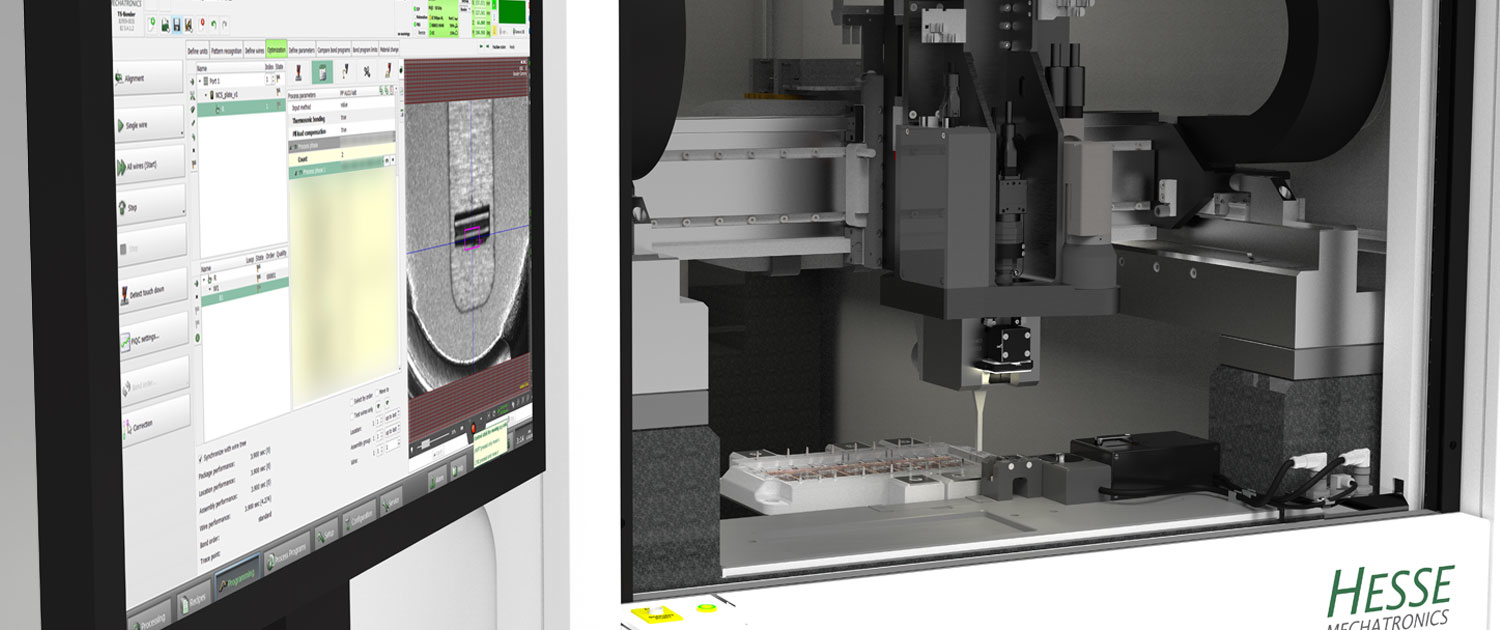

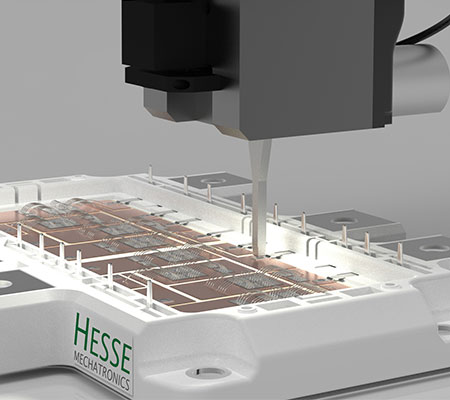

- Image recognition for detection and correction of weld locations

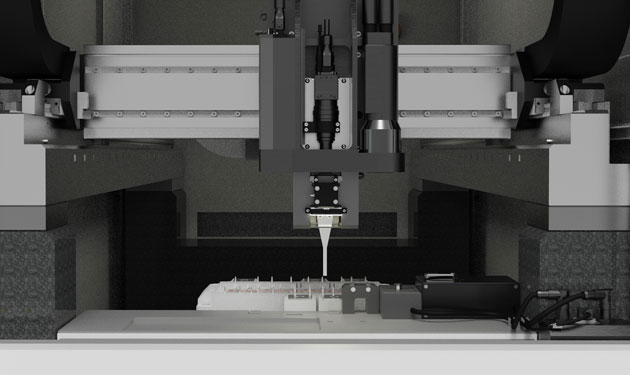

- Active vertical axis

- Rotational p-axis for angle optimized process results

- Wide range of ultrasonic (US) power

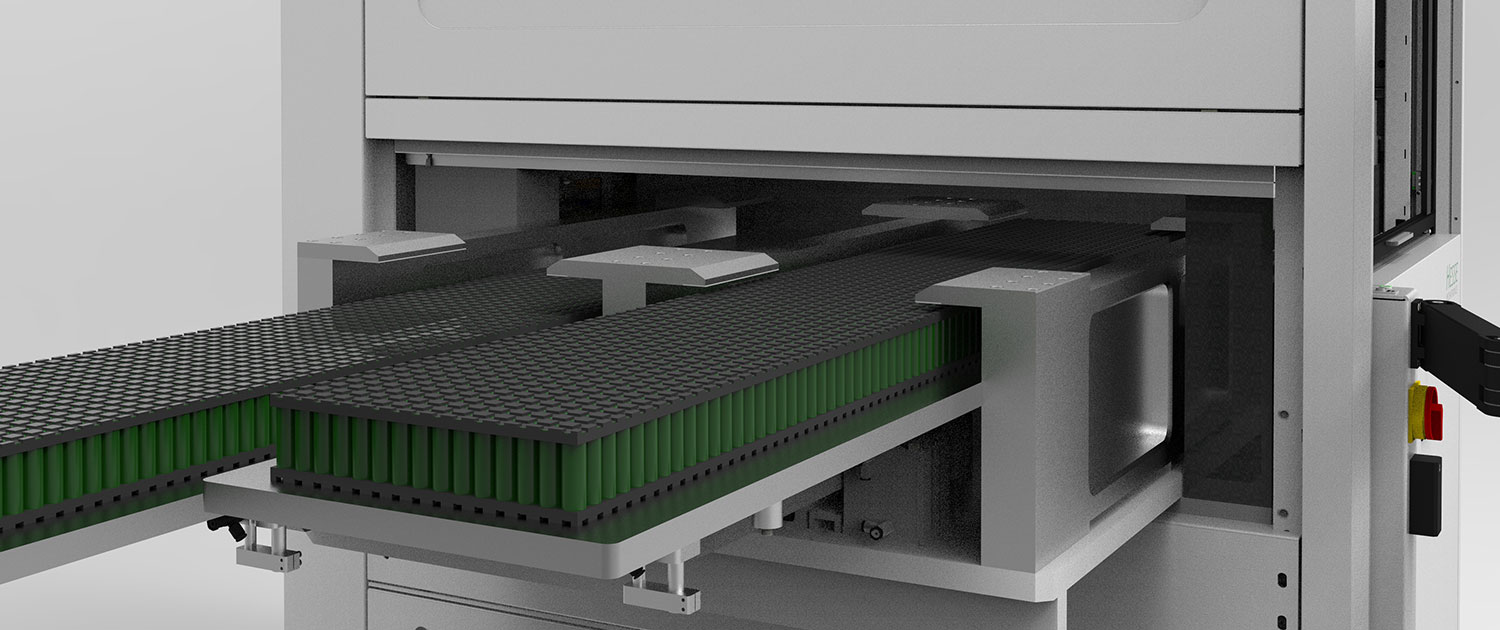

- Ultrasonic welding as cell contacting system for battery applications

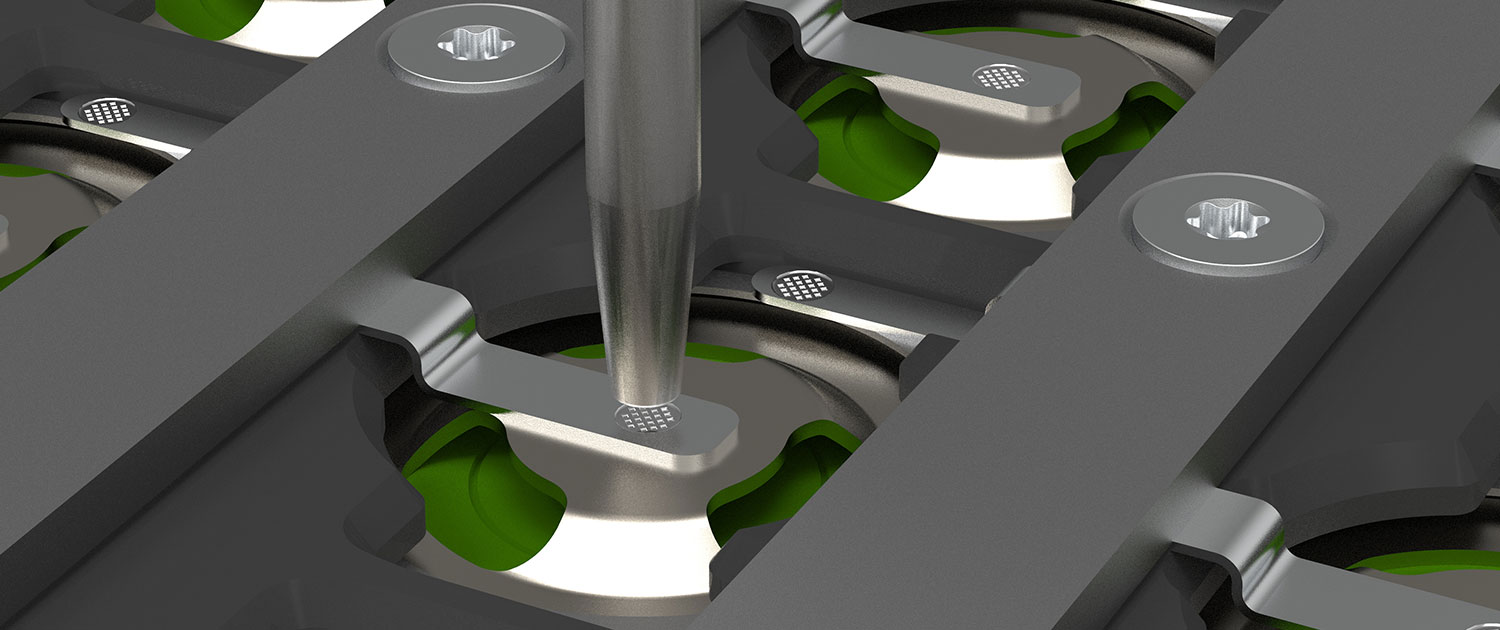

- Narrow pitch and deep access due to long, narrow sonotrodes and pattern recognition supported positioning

- Zero gap is performed by touchdown process not by clamping

- Touchdown sensor to avoid damage to sensitive contact components

- Precise and dynamic force control

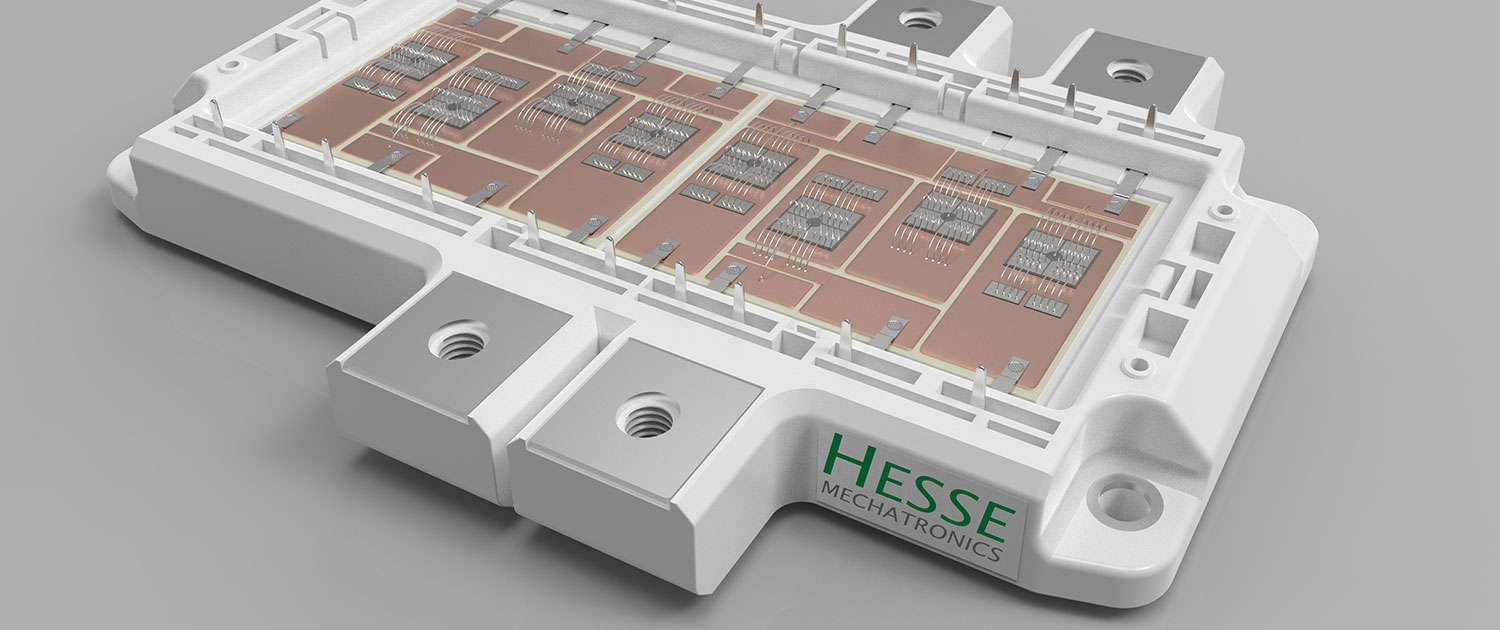

- Programmable welding maps with multi-interval processes

- Individual parameters per weld

- Flexibility to handle a large variety of products

- Standardized interfaces for line integration

- Automotive accepted process control (PiQC, patented)

Flexibility

- Working area: max. 374 mm x 883 mm

- Flexible use of the working area, e.g. vacuum clamping

- Maximization of throughput by automation (two/more parallel lanes)

Quality

- Process integrated Quality Control (PiQC): detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); as option

- Full traceability of all relevant process data

Technical data

Working area

- Equipped with 400W weldhead:

- X: 374 mm; Y: 857 mm; Z: 60 mm

- P-rotation: 380°

- Equipped with 1500W weldhead:

- X: 374 mm; Y: 777 mm; Z: 54 mm

- P-rotation: 380° centrally, 2 x 180° at travel range limits

Mechatronic weldheads

- Weldhead for up to 400W

- Weldhead for up to 1500W

- Rotational p-axis head

- Longitudinal transducer system

- Electronically controlled weld force actuator

- Precise touchdown control (force and speed)

Ultrasonic

- Wide range of US power

- Programmable ultrasonic power output

- Programmable process profiles

Footprint and weight

- SW1085: 880 mm x 1780 mm x 1912 mm, (W x D x H, excl. monitor and light tower), appr. 1800 kg

Video