Benefits and Features

Advanced features and process advantages

- Bondheads for all common wire materials

- Wear-free components with piezo technology

- Maintenance-free flexure hinges

- Working area: X: 100 mm; Y: 150 mm ; Z: 42 mm

- Intelligent bondhead connecting system with integrated memory storing all calibration data: bondheads are interchangeable within a few minutes

- Optimized pattern recognition

- Use of all common wire spools

- Loop generator for customized loops

- Integrated, non destructive pulltest for wire and ribbon (HBK, RBK)

- Continuous, real time monitoring of wire deformation, transducer current and frequency within programmable control limits

- Machine mobility by mounted rollers; as an option

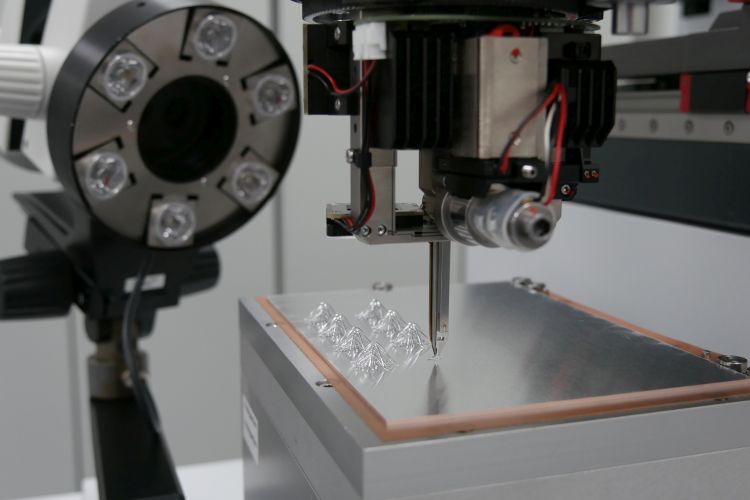

Heavy Wire Bondhead (Al)

Heavy Wire Bondheads for wire bonder Bondjet BJ653

Heavy Wire Wedge-Wedge Bondheads

- Heavy wire and ribbon bondheads for aluminum, copper and AlCu:

- HBK (Frontcut, Backcut); frequency: 60 kHz*

- RBK Ribbon (Frontcut); frequency: 57 kHz*

- RBK Copper (Frontcut, Backcut); frequency: 57 kHz*

alternative frequencies available on request

- Wire Al, Cu, AlCu: 50 μm – 600 μm

(2 mil – 24 mil)** - Ribbon Al, Cu, AlCu: 250 µm x 25 µm up to 2000 µm x 400 µm

(Cu: 200 µm) (10 mil x 1 mil up to 80 mil x 16 mil)** - Cutting methods:

- Active Cutting: repeatable, precise, programmable cutting depth

- Air Cut: No impact on surface, e.g. for highly sensitive chips because of „touch-free“ cutting

- Passive Cutting

- Integrated, non destructive pulltest

- Process integrated Quality Control PiQC: detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); available as an option

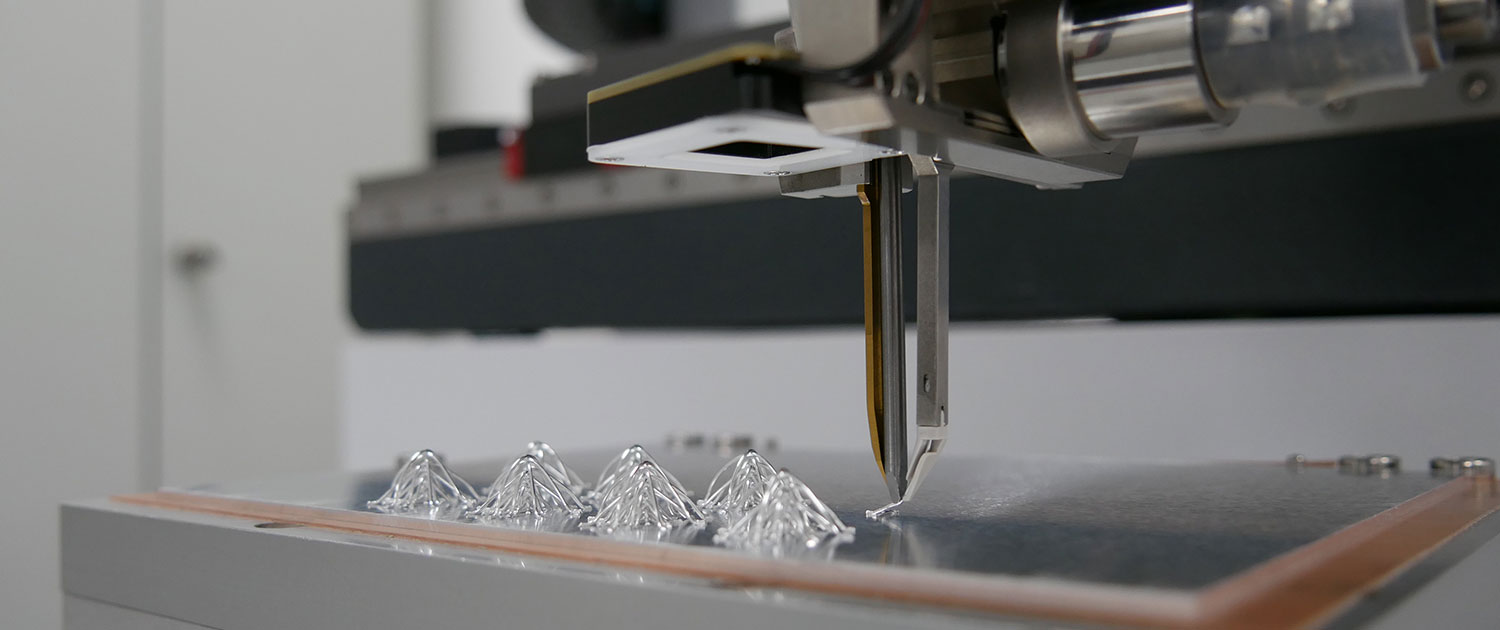

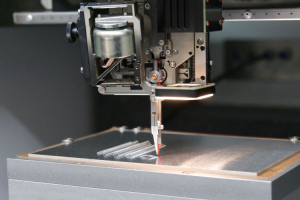

Bondhead for Ribbon

Heavy Wire Loop Design

- Reproducible loop geometrics by wire guide appropriate for the material (e.g. pulling wire buffer)

- Loop form functions: constant wire length, constant loop height, individual loop shapes

- Mechanically demanding loop geometrics by parameterization and individual wire clamp application

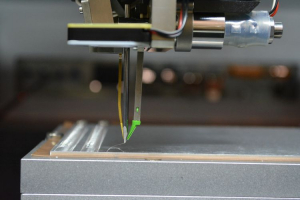

Heavy Wire Bondhead 50 µm

Fine Wire Bondheads for wire bonder Bondjet BJ653

Fine Wire Wedge-Wedge Bondheads

- Bondhead 45° and 90° (deep access)

- Frequency: 100 kHz*; alternative frequencies available on request

- Wire Al, Au: 12.5 μm – 75 μm (0.5 mil – 3 mil)**

Cu: 17.5 μm – 50 μm (0.7 mil – 2 mil)** - Ribbon: Al, Au: 35 μm x 6 μm up to 250 μm x 25 μm

(1.4 mil x 0.25 mil up to 10 mil x 1 mil)** - High precision touchdown detection without time delay, e.g. for bonding on very thin substrates

- Precise bondforce control (static and dynamic)

- Process integrated Quality Control PiQC: detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); available as an option

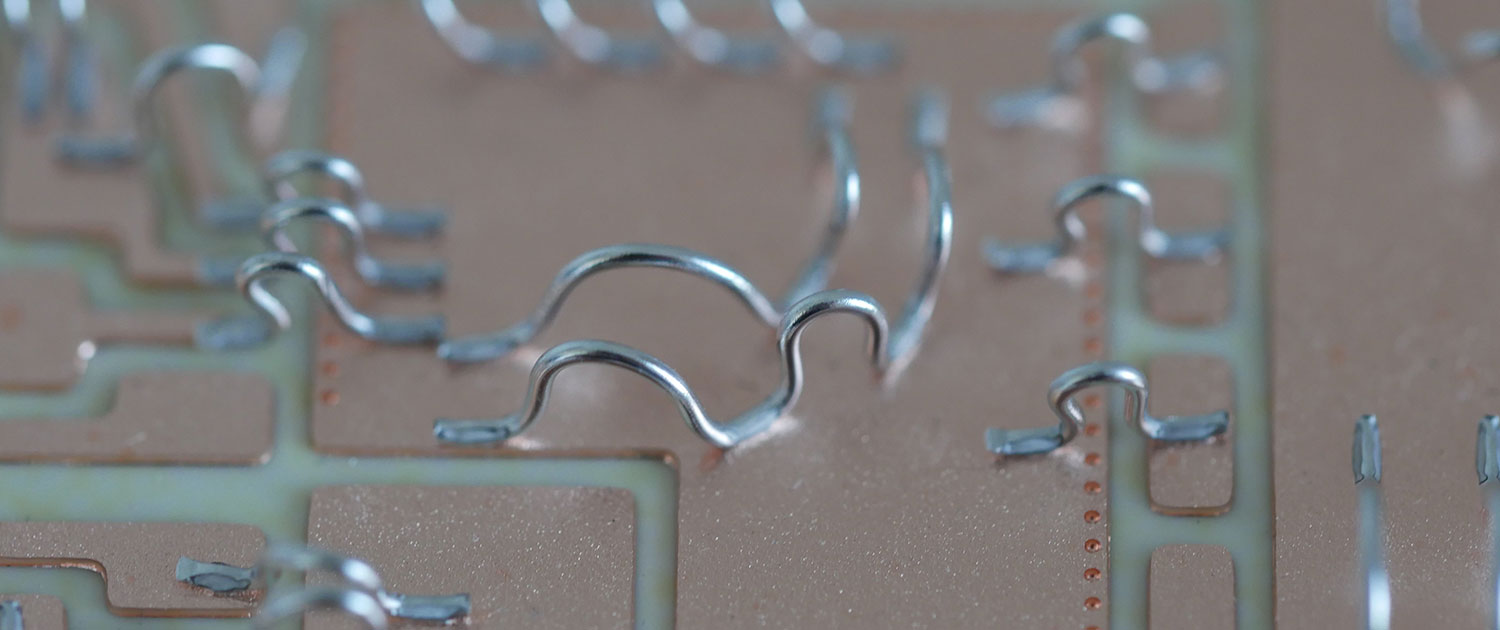

Fine Wire Wedge-Wedge Loop Design

- Loop form functions: constant wire length, constant loop height, individual loop shapes

- Fine pitch: 40 µm in-line, 25 µm staggered/dual-line (depending on wire and loop)

- Freely programmable wire feed, tail length, tear stroke and opening gap of wire clamp

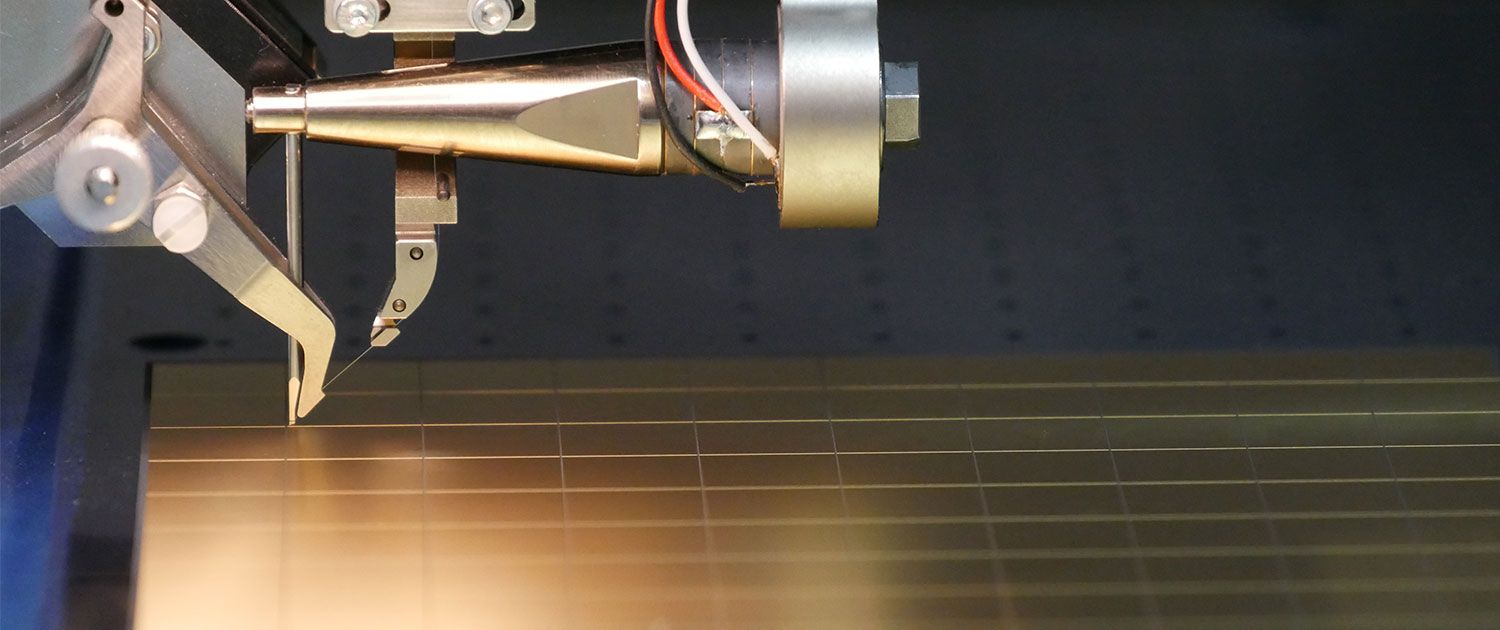

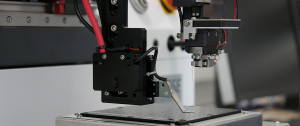

Ball-Wedge Bondhead

- Thermosonic ball-wedge bondhead

- Frequency: 120 kHz*

Option: Dual-Frequency 120/60 kHz* - Wire: Au 17.5 µm – 50 µm (0.7 mil – 2 mil)**

- 11/19 mm capillaries

- Ultrasonic in preferred direction by bondhead rotation

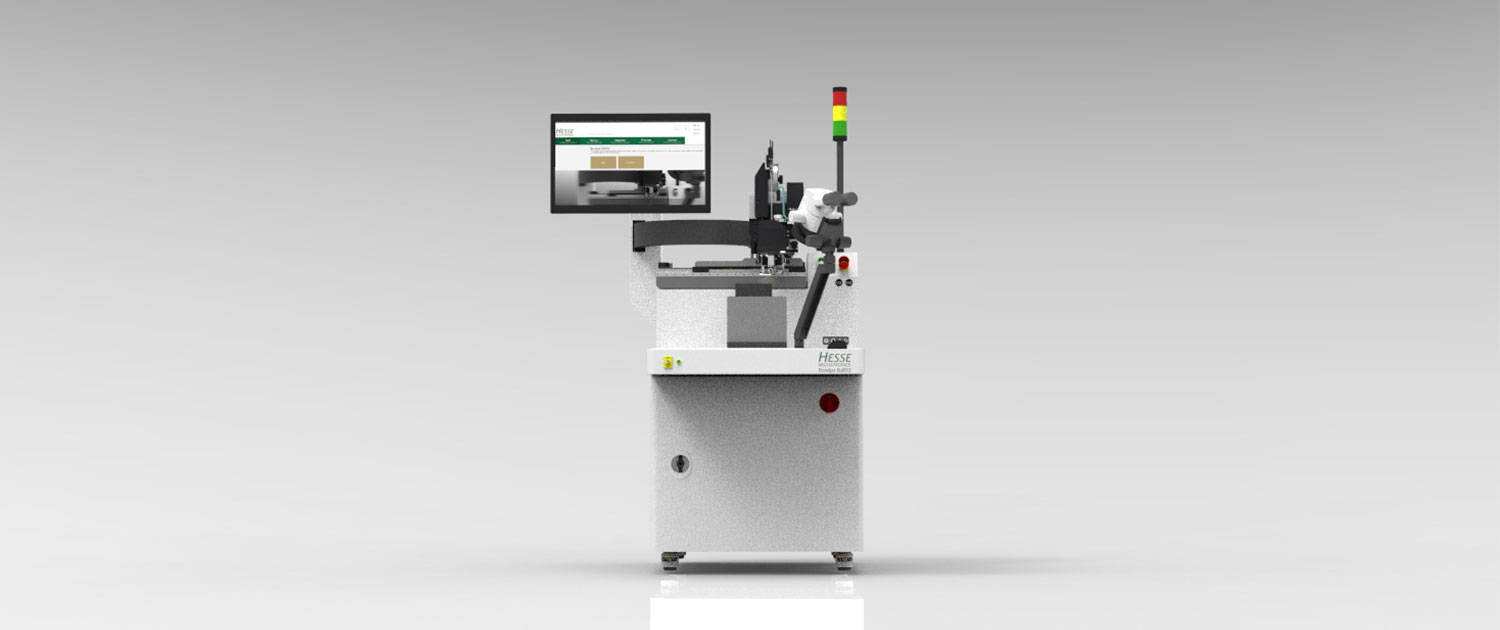

Technical Data

- Open working area BJ653: X: 100 mm; Y: 115 mm; Z: 42 mm

- P-rotation: 440°

- Digital ultrasonic generator with PLL (Phase Locked Loop), internal frequency resolution <1 Hz; programmable ultrasonic power output

- Windows® Embedded operating system

- Height of operator desk: 730 mm

- Footprint: 700 mm x 1020 mm x 1409 mm (W x D x H, excl. monitor and light tower)

- Weight: approx. 330 kg, depending on configuration

Ball-Wedge Bondhead

* exact range of frequencies on request

**depending on application and wire

Video