Ultrasonic Wire Bonding for Battery Connections and Power Modules

400 µm Al wire on shoulder

Al ribbon connecting prismatic cells

Bonding on different levels

Ultrasonic Wire Bonding for Battery Connections and Power Modules

Ultrasonic wire bonding is one of the most flexible and beneficial joining technique of batteries and power modules. It is used in the production of battery packs for applications such as of power electronics and conductor elements.

- Battery cell contacting system

- Current-carrying contacts

- Contacts for cell voltage monitoring

- Battery cell interconnection system: Cell to cell, cell to busbar, cell to PCB, and other electrical connections

- Electrical connection to the battery management system (BMS)

- Fully programmable and tolerance compensating production process

Advantages of ultrasonic wire bonding

Automation: Manual and fully automated operation

The precise and safe handling of the battery packs in and out of the production machine plays a significant role in controlling the product quality, yield and efficiency of the production equipment. For this reason Hesse GmbH is offering standard components as well as individually adapted automation concepts. Get more details on our page for automation solutions.

Process Support: We support you in developing and implementing your individual process requirements for connecting your batteries. Our range of services includes:

- Sample Bonding

- Pre-Production Prototype

- Design Validation Builds

- Small Series Production

- Module Production

- Process Optimization

Get more details on our page for Customer Solutions.

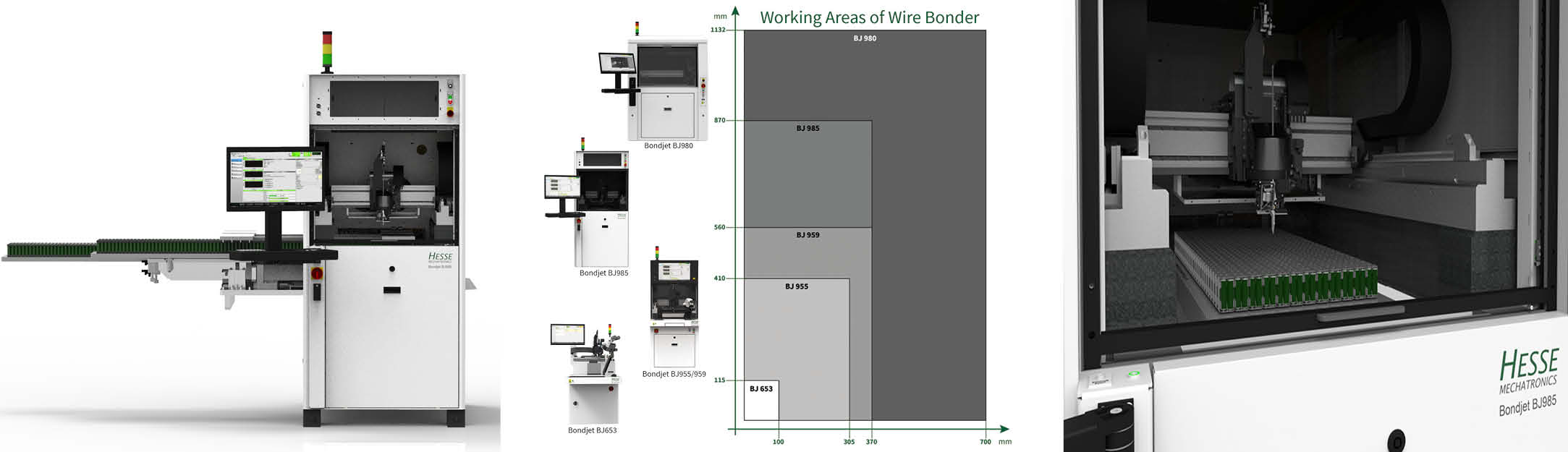

Find the suitable Wire Bonder for Your Battery Connections!

Give us a call +49 5251 1560-0 or send us your requirements with the contact form below.

Please ask us to send you our battery brochure „Battery Connections with Ultrasonic Wire Bonding“

Contact Form for your Battery-Connections!