Software Options

For the growing demand of connectivity and industry 4.0

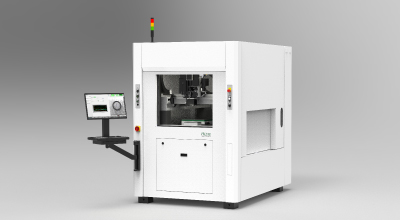

The Laser Welder LW1089 is a laser welding system for fully and semi-automatic deep penetration welding of aluminum and copper leads on DCB substrates, in power electronics, battery cells and modules, or other electronics manufacturing components. Laser welding uses a laser beam to create intermetallic joints along a weld seam.

Both temporal and spatial laser power modulation enable different weld geometries and depths with the Laser Welder LW1089. A movable holding-down device avoids contamination of the surrounding area by weld pool ejections („splashes“) during the welding process.

Constant precision throughout the manufacturing process is ensured by high axis accuracy and a professional process control, which ensures reproducibility of clamping force („zero-gap-challenge“) and welding conditions. This standardized „clamp and weld“ concept offers fast adjustment to different product variants and flexible product changeover. It also makes it possible to react automatically to component tolerances of the joining partners to be welded.

Laser Welder LW1089

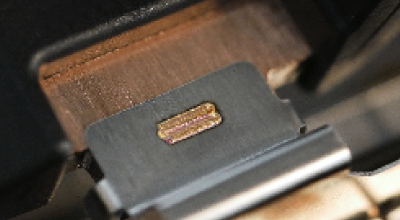

Laser welded application example

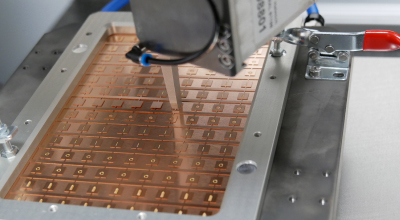

Laser weldhead

Working area

| Laser Welder | X | Y | Z |

| LW1089 | 410 mm | 480 mm | 75* mm |

| P-rotation: 360° | |||

| W x D x H [mm] | |

| LW1089

excl. attached parts like e.g. control panel, status lamp |

1480 x 2150 x min. 2092 |

| External switch cabinet

excl. attached parts like main switch, door handles |

800 x 1000 x 2100 |

(*depending on product configuration)

Please complete the request form using the button and enter your name and business e-mail address. A download link will be sent to you after verification.

For the growing demand of connectivity and industry 4.0

Standard components or individually adapted solutions

Read our article about “Efficient Laser Welding Systems”