Wire Bonding Innovation: Plug & Produce

Published in: SMT Insight / Issue 1 – 2017 / February

Author: Sebastian Holtkämper, Product Management, Hesse GmbH

The evolving grade of automation in the semi-conductor business is fostering both the increasing robustness of processes and the reduction of its cost. These two drivers are a recognized customer wish. The term “Plug & Produce” is the answer to this trend and describes the idea of the ease of scalability of machine count and its integration in existing production processes. To avoid a costly and complex job between set up (“Plug”) and start of production (“Produce”), the machine needs to provide a certain intelligence and autonomy. State of the art wire bonders have the capability of coming close to this ideal.

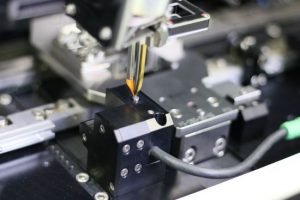

1-Automated bond force calibration

Conventional wire bonding is still subject to manual interventions, which on the one hand results in downtime or requires downtime. On the other hand, manual actions mean a disturbance variable for quality compliance, e.g. measurement errors or contamination. The wedge tool for example, is subjected to continuous abrasive and additive characteristics during its life time. This occurs due to the energy input required to build up the connection between the wire and chip surface or wire and substrate surface. Therefore, a cyclical change of the wedge tool becomes necessary. In a similar way the consumable wire requires manual intervention when a new spool is mounted.

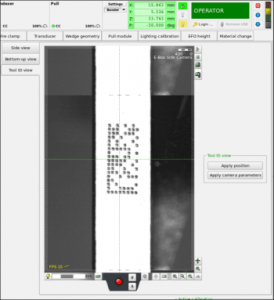

Depending on the type of consumable, calibration (Picture 1), adjustment and monitoring must take place after exchange, which can be executed automatically or semi-automatically. Mechanical mechanisms with force and position sensors as well as optical systems including pattern recognition (Picture 2) reduce operator error and shorten the setup and conversion times. Additionally it enables complete automatic traceability. For the process and the product this is a remarkable improvement and an increase of efficiency and reliability compared to manual adjustment means.

2: Only a correctly detected bond tool can trigger the production release

Besides the automation on process side, Plug & Produce describes the ease of integration of new machines into existing production lines. This is supported by a controlled synchronization. Line management can be implemented from any of the connected wire bonders. Production programs, libraries of material and general settings are automatically adopted from existing machines. A super-ordinate server system or a manual transfer or copying is no longer necessary. Beyond these advantages, the installation of such a bonder network is a benefit for the security of data and production. De-centralized data storage minimizes the risk of a black-out.

Due to the high degree of technological sophistication, innovations in wire bonding require integral consideration of the entire system. A fusion of the know-how in software, hardware and processes are a premise for a successful, forward-thinking development in the semi-conductor packaging business. Furthermore, the communication and cooperation of the production’s infrastructure is being respected when developing prospective systems, bearing the readiness for industry 4.0 in mind

Download german article as PDF.

“A high degree of automation in production machines does not automatically deliver a wise solution for each customer. The best solution for the processes is rather achieved by a smart kit system consisting of intelligent modules – tailor- made and for highest efficiency“ Sebastian Holtkämper, Hesse GmbH, Produktmanagement