Benefits and Features

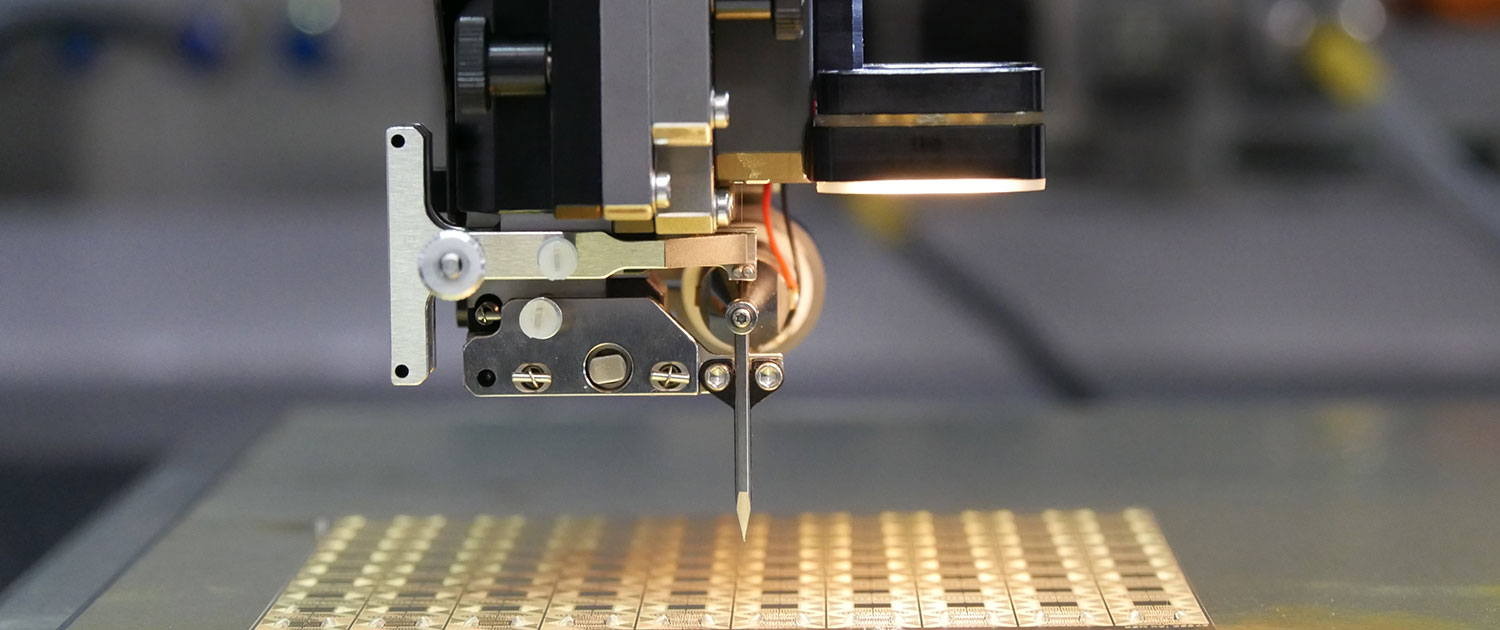

Advanced features and process advantages

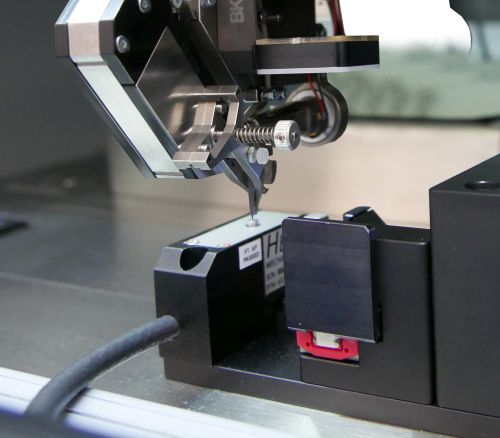

- High precision touchdown detection without time delay, e.g. for bonding on very thin substrates

- Optimized pattern recognition: image capture with new digital image processing and flash

- Hesse Assist Tools (option):

- E-Box: patented solution for optimized tool change and

programmable alignment marks for wedge and wire clamp - Automated bondforce calibration; a load cell prevents operater error and ensures robust processes

- Innovative bondtool detection

- E-Box: patented solution for optimized tool change and

- Automated bondtool calibration without wedge gauge

- Loop generator for individualized loops

- Wear-free components with Piezo technology

- Maintenance-free solid state joints

- Pre-setting of bondheads via EEPROM

Fine wire (Au) with mit ball-wedge bondhead

Flexibility

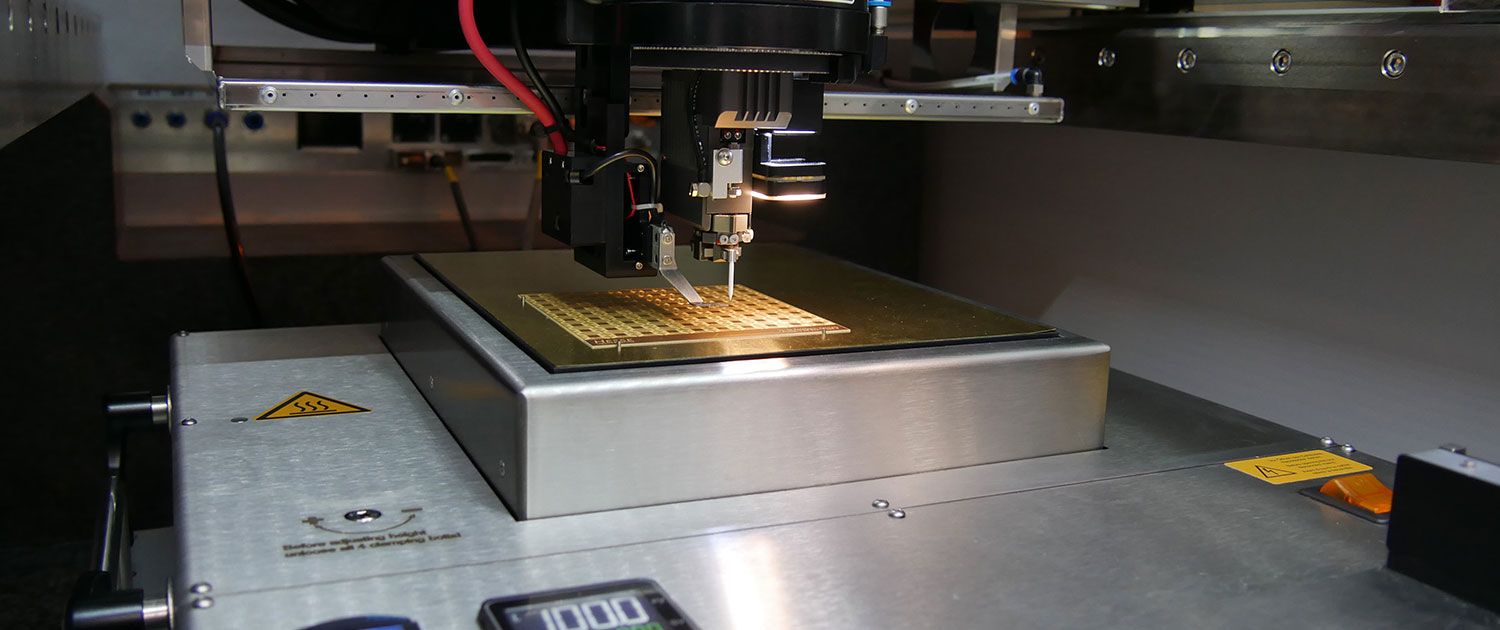

- Flexible use of working area, e.g. with a number of bonding stations (manual loading or with indexers)

- Universal software interface for indexer control

- Maximization of throughput by automation with two or more parallel lines

Speed

- Up to 7 wires per second, depending on application and bondhead,

e.g. wedge-wedge bondhead, 25 μm wire, 1 mm loop length, metallized wafer

Quality

- Continuous real time monitoring of wire deformation, transducer current, frequency and impedance within programmable control limits

- Process integrated Quality Control PiQC (as option): detection of further parameters by additional sensor system for 100 % quality monitoring in real time (patented)

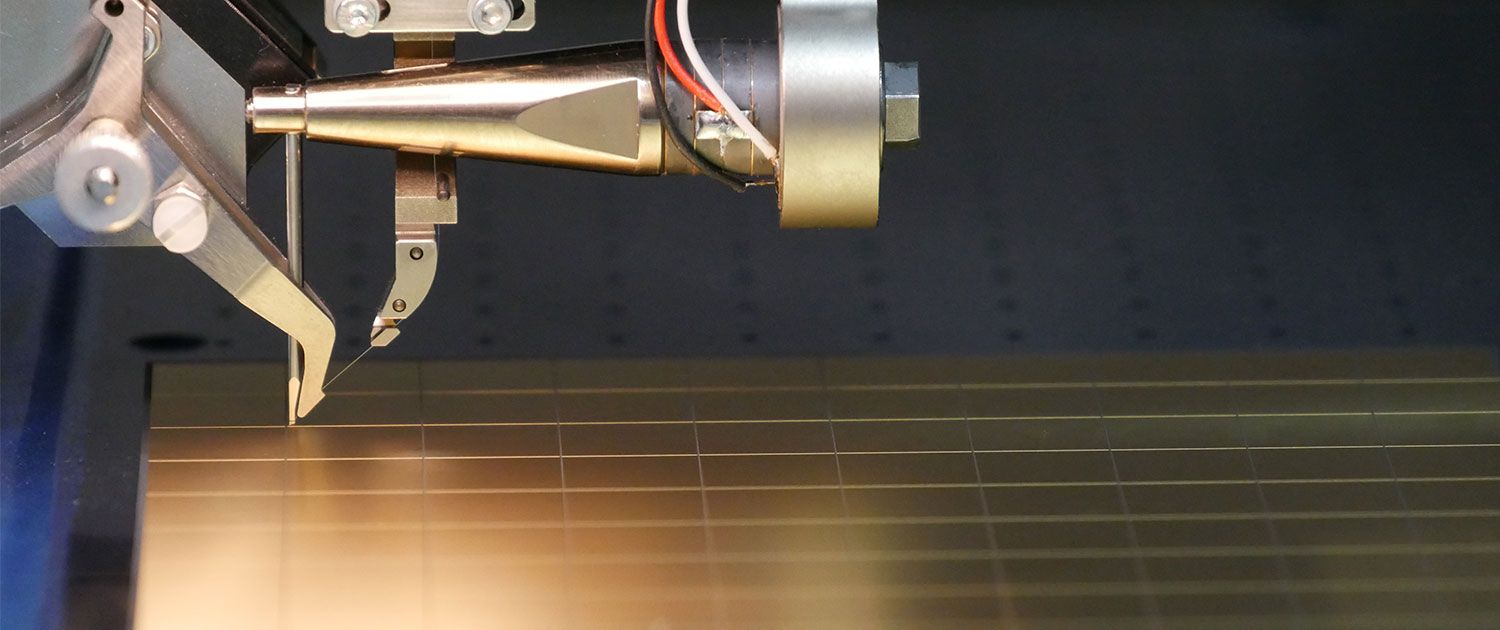

Wedge-Wedge bondhead for wire bonder Bondjet BJ885

- Bondhead 45°, 60° and 90° (deep access)

- Freely programmable wire feed, tail length, tear stroke and opening gap of wire clamp

- Precise bondforce control (static and dynamic)

- Bondheads can be replaced in minutes

Fine wire wedge-wedge bondhead

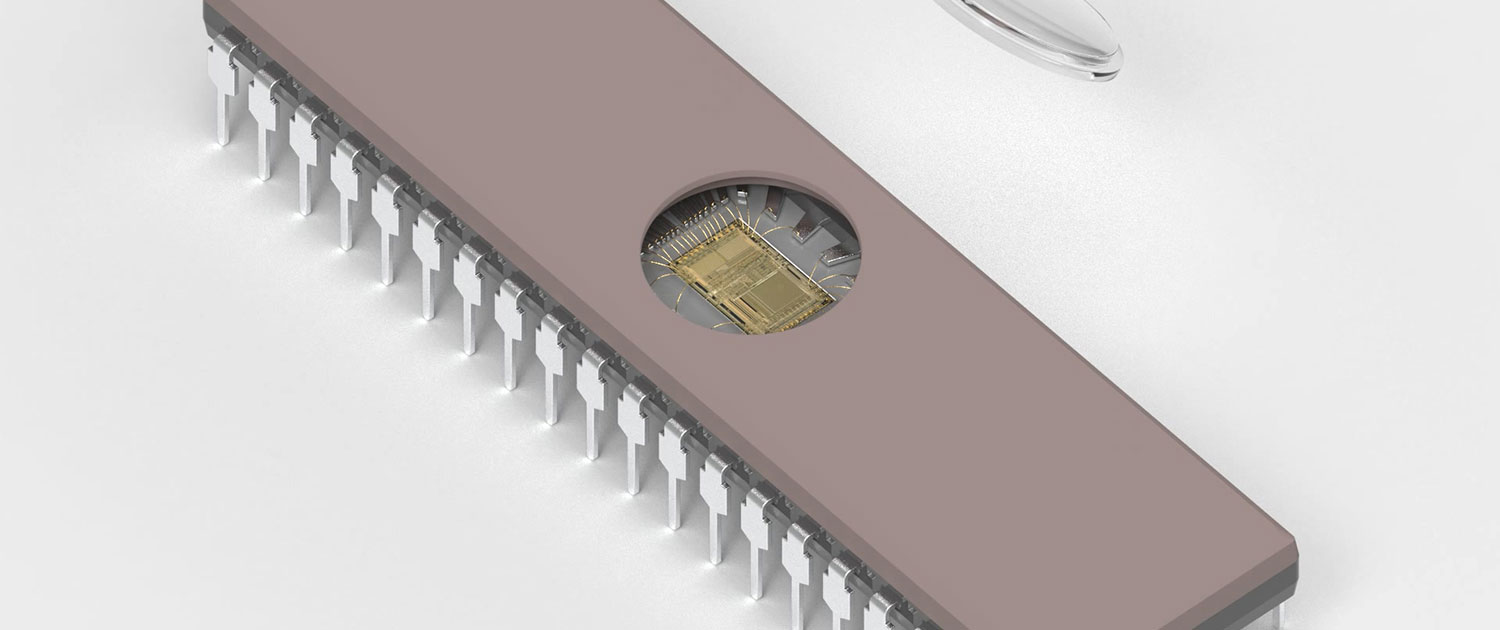

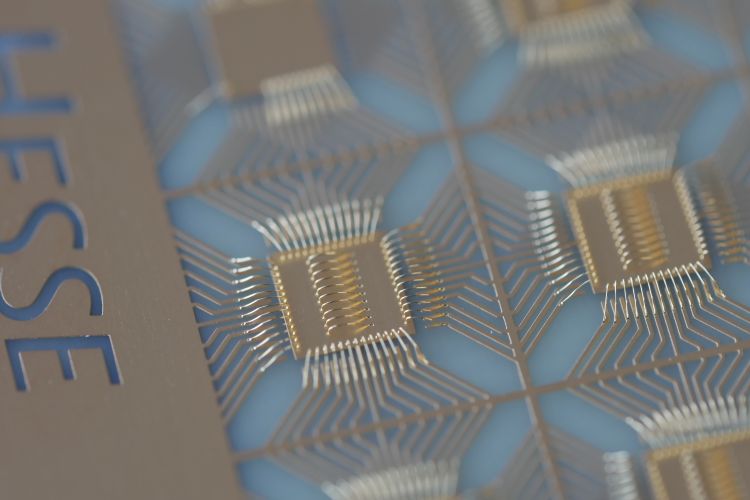

Ball-Wedge bondhead for wire bonder Bondjet BJ885

- Multi-level bonding according to Z axis stroke of 31 mm

- 11/19 mm capillaries

- Ultrasonic in preferred direction by bondhead rotation

- Height adjustable NEFO arm

- Dual frequency possible

Ball-wedge bondhead for wire bonder BJ885

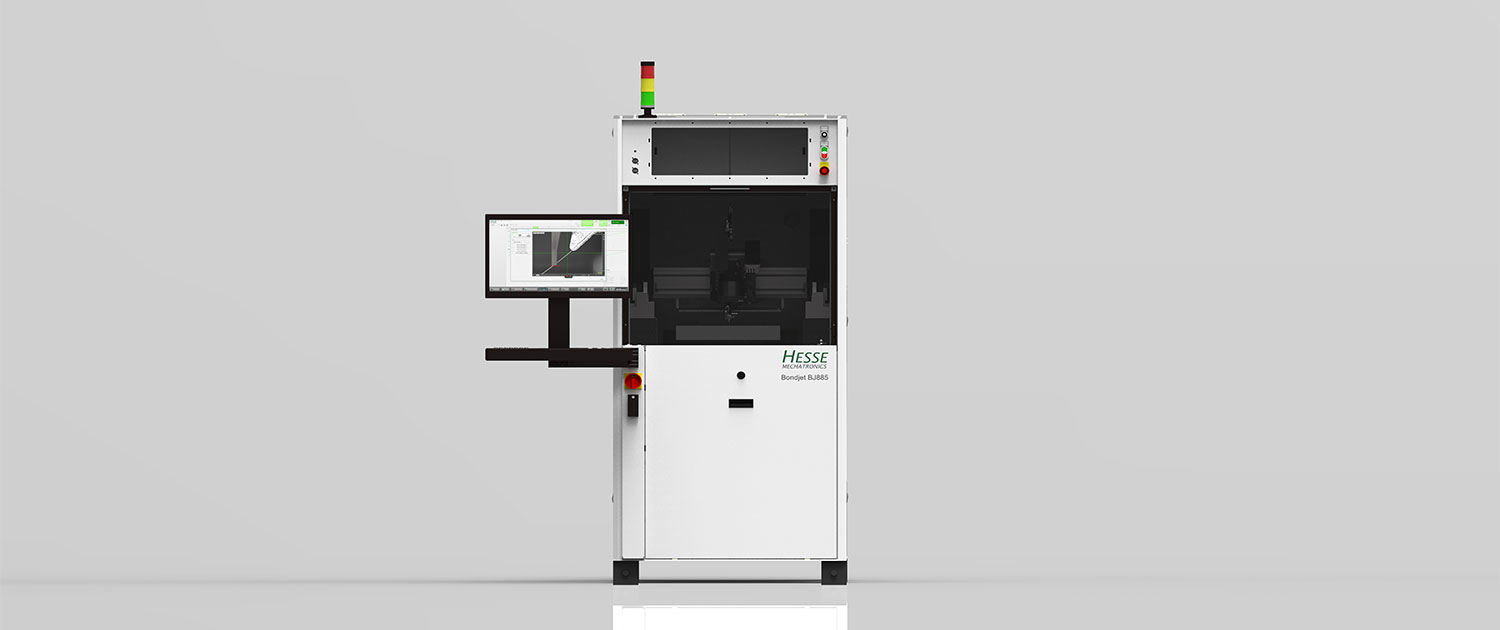

Technical data

Working area

- X: 370 mm; Y: 870 mm

- Z stroke: 31 mm

- P rotation: 440° for wedge-wedge head, 180° for ball-wedge head

Mechatronic bondhead

- Wedge-wedge bondhead 45°, 60°

- Wedge-wedge bondhead 90° (deep access) for ribbon or wire

- Ball-wedge bondhead

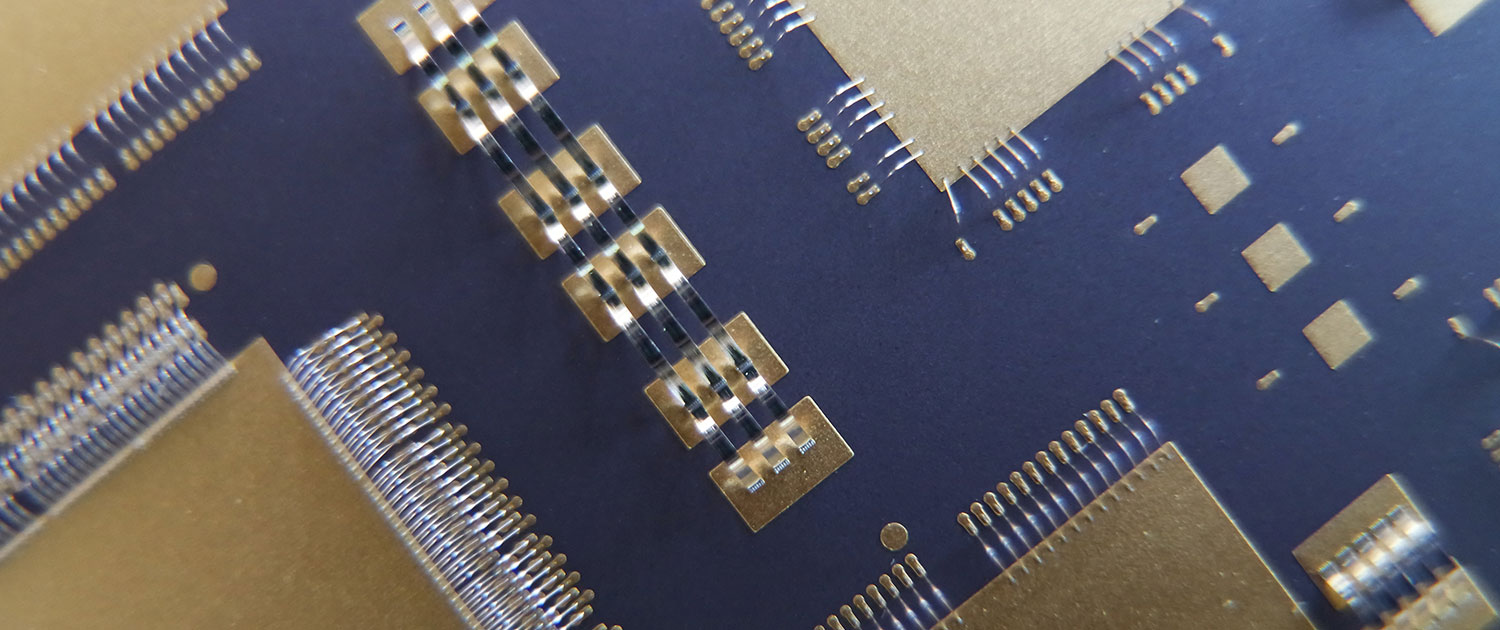

Wire

- Al, Au, Ag, Cu, Pt: 12.5 µm – 75 µm*(0.5 mil – 3 mil)*

Ribbon

- Al, Au: 35 µm x 6 µm up to 250 µm x 25 µm*

(1.4 mil x 0.25 mil up to 10 mil x 1 mil)*

Fine wire loop design

- Loop generator for individualized loops

- Loop form functions: constant wire length, constant loop height, individual loop shapes

- Fine pitch (wedge-wedge): 40 µm inline, 25 µm staggered/dual line (depending on wire diameter and loop)

Footprint and weight

- 880 mm x 1780 mm x 1912 mm (W x D x H , excl. monitor and light

tower) - Weight: approx. 1800 kg

* depending on bondhead, application, wire

Video